Product Knowledge

A wide selection of coated abrasive is produced by NCA to meet the requirements of any application. Selecting NCA products is the best way to secure the highest performance rate at reduced cost for any given sanding operation.

Coated abrasive products are made from three basic raw materials: a mineral, a backing and an adhesive bond. The raw materials purchased through strict quality control to ensure the highest quality of NCA products.

Minerals

- Garnet – reddish brown

Medium hardness, with good cutting

Edges : used in wood working - Aluminium oxide – gray brown

Tough, sharp, and used for finishing hardwoods and high tensile strength metals such as alloy steels and high carbon steels. - Silicon carbide – shiny black

Except for diamond, the hardest mineral to be used for polishing low tensile metals such as aluminium, brass, copper, and also non-metalic materials such as glass, plastic and synthetic leather.

Adhesive

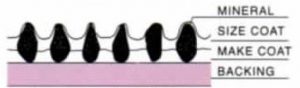

Coated abrasives have two adhesive layers. The first is called “make coat” which hold the minerals to the backing, the second is called “size coat” which fixes the minerals in position.

- Glue

Straight animal hide glue is used for both the make coat and the size coat. - Resin

Phenolic and epoxy resins are used in NCA products. They are exceptionally resistant to heat and moisture.

Backings

- Paper

A weight paper is the lightest weight paper used as backing.

C and D weight papers are intermediate weight paper.

E weight paper is a strong, heavy duty paper and is used in belt from and sheets for drum sanders.

V weight conrived by NCA consists of two layers of Ewt paper to from a exceptionally tough backing for the sectional belt used in the particle board industry. - Cloth

J (jeans) is light and flexible.

X (drill) is durable and strong.

Cloth backings are used both for hand and mechanized sanding operations. - Fibre

Fibre is made from a rag stock paper which has been condensed and hardened, when finished, is strong, tough, relatively hard, and has much more body than any of the other backings. - Combination

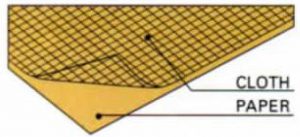

Papar and cloth are laminated together to form a sturdy and shoch resistant backing.

Forms

- Roll

- Belt

- Disc

- Sheet

Storage and handling of coated abrasives

Coated abrasives can be expected to perform at maximum efficiency only when they receive proper handling and treatment.

Major points to be attended.

- Avoid dampish place and direct exposure to sunlight.

- Avoid storage close to the source of heat.

- Optimum at temperature ranging from 15o C to 25o C and at 50 to 65 percent relative humidity.

- Belt pegs or hangers should be as wide and thick as practicable.

- Avoid putting abrasive belt on a concrete floor directly.

- Avoid excessive tension for the abrasive belt.

- Grinding pressure should be as mild as practicable, especially at the initial stage of the belt life.